Product Description:

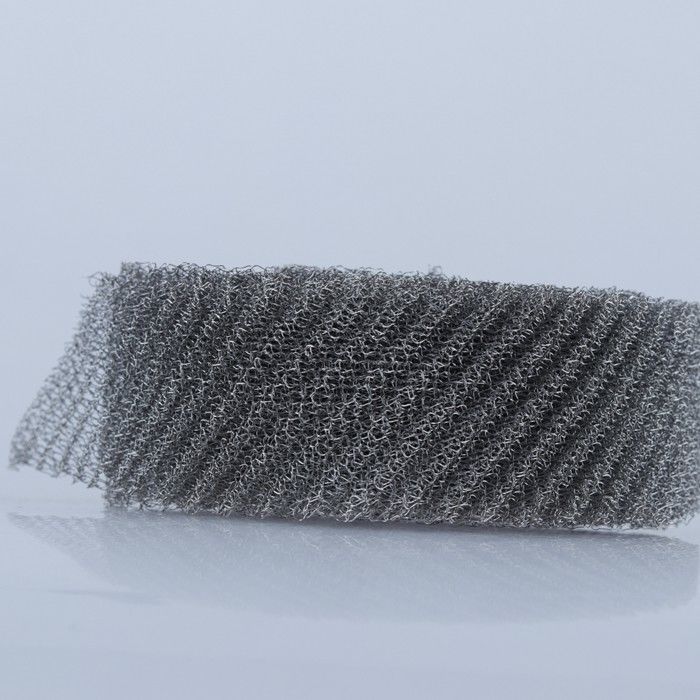

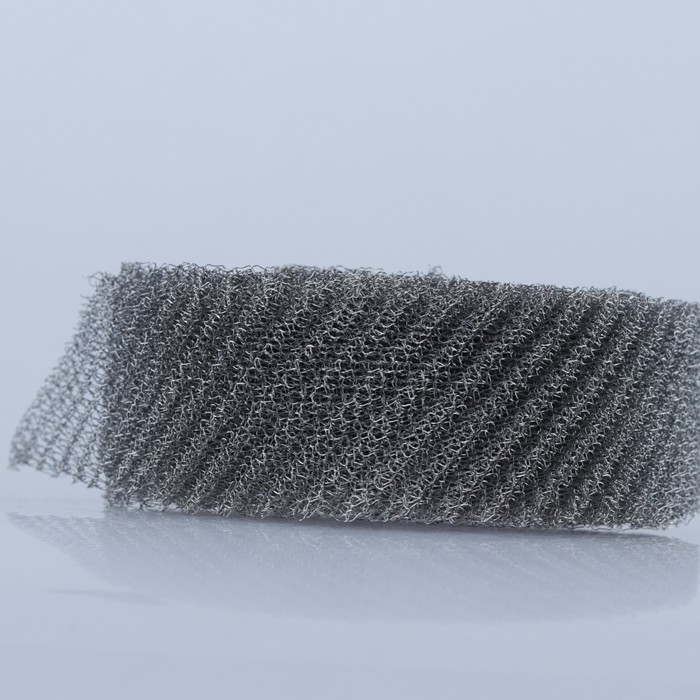

Stainless steel knitted mesh refers to knitted mesh made of stainless steel wire. It is a nonwoven wire mesh or cloth product. The stainless steel knitted mesh is the most widely used type among all material knitted meshes

Stainless steel knitted mesh can be made of mono-filament or multi-filament. Mono-filament knitted mesh is the simplest type, which can be used in the common applications; whereas the multi-filament knitted mesh has higher strength, which can be used in the heavy duty applications

The stainless steel knitted mesh is manufactured using a knitting process where the mesh is formed from a series of interlocking loops. The original stainless steel knitted mesh is flattened when complete production, but it can be made into ginning knitted mesh by machine according to customers' requirements. Ginning knitted mesh has different shapes, width and depth of ginning, which can suit more applications. Additionally, stainless steel knitted mesh can be compressed into compressed knitted mesh for better filtering efficiency

Features

High Strength and Overal Rigidity: Our filter has high strength and overall rigidity, providing superior support for good air permeability and excellent filtering accuracy

Exceptional Filtering: The filter also has excellent filter resistance, mechanical strength, abrasion resistance, heat resistance, and cold resistance. Plus, it is easy to clean and simple to assemble with a long replacement cycle

Customized Sizes: Special sizes can be customized according to customer specifications

Technical Parameters

| Property |

Value |

| Opening size |

2mmx3mm To 4mmx5mm To 12mmx6mm

Special sizes: Customized |

| Mesh shape |

Flat Type And Corrugated Type |

| Weaving style |

Knitting |

| Width |

40mm 80mm 100mm 150mm 200mm 300mm 400mm 500mm 800mm 100mm Etc |

| Woven style |

Single Wire Woven, Double Wires Woven, Several Wires Woven |

| Wire diameter |

0.07-0.55mm, Common Wire Diameter, 0.2mm-0.25mm |

| Material |

304, 304L, 316, 316L, 430, 410 Stainless Steel Wire |

| Keyword |

Stainless Steel Knitted Mesh, Gas Liquid Filter Mesh |

| Standard Forms |

Standard Type, High-efficiency Type, High Wear Type, Damping Type |

| Oil Demister Knitted Mesh |

Knitted Wire Mesh Filters, Knitted Wire Mesh Filters, Mesh Filter Sleeve |

Applications:

Oil-Gas Separation

Oil-gas separation is a critical task that allows for the collection and reuse of hydrocarbons. It can be applied to a broad range of products, from refining crude oil to filtering turbine exhaust. The process is generally used with either recycled or fresh hydrocarbons. The first step of oil-gas separation involves mixing the hydrocarbon with a liquid or gas that allows for the separation. This can be accomplished by either having two parallel streams or one stream carried by a mechanical system. The next step is to separate the oil and gas. This can be done through various methods such as stripping, distillation, and filtering

Air Purification Filters

Air purification filters are an essential element in many machinery and equipment used in industrial and automotive applications. T hese filters serve the essential role of capturing and removing potentially hazardous allergens, dust, smoke, and other pollutants from the air. Air purification filters come in various sizes and materials, from HEPA filters to deep-bed filters that capture ultra-fine particles. Air purification filters also help to prevent the buildup of contaminants and particles in machinery and equipment, helping to ensure their longevity and reduce operating costs. Furthermore, these filters improve air quality, making it safer and more pleasant to work and live in

Sealing

Sealing is a crucial process used in a range of industries, from automotive to pharmaceutical and medical. It serves the fundamental role of preventing liquid, gas, and fluids from entering or exiting a space, as well as from bonding two separate components. These seals vary in design and material, such as rubber and cork, with some being designed for extreme temperature ranges, pressure, or to form a gasket or liquid seal. Whatever the specific use, seals provide a barrier between components and the elements and help to ensure a safer product

Damping and Shocking Proof

Damping and shocking proofing is used in a range of applications to reduce or absorb vibrations from machinery or impacts. Damping materials are typically made of a soft rubber or plastic material that are used to reduce the amount of force that is transmitted from one contacting surface to another. Shockproofing is a process used to reduce the chances of an object failing due to a sudden jolt or sharp impact. These materials are often made of the same type of resilient material and are used to protect the component from potential shock or vibration damage

Silencers and Exhaust Gas Purification Components

Silencers and exhaust gas purification components are key components for automotive engines. Silencers serve the critical purpose of reducing engine noise. The materials used can vary, from rubber and foams to specialized sound-absorbing materials. Exhaust gas purification components are also important, and can typically consist of a range of filtration systems, catalytic converters, and other materials. These components help to reduce emissions by breaking down harmful exhaust gas into more manageable compounds, helping to benefit the environment

Electronics and Electrical Products EMI Shielding Devices

Electronics and electrical products EMI shielding devices are essential for protecting electronics from electromagnetic interference. These devices are typically used on products such as high-powered alternators and sophisticated wiring systems. EMI shielding devices vary in design and material, and are often specifically designed for a particular application. These products can help to reduce noise interference, eliminate unwanted radio frequencies, and protect the system from potential power surges. They also have a key role in providing consistent performance and operational safety

Support and Services:

Stainless Steel Knitted Wire Mesh Technical Support & Service

- 24/7 customer service

- Free technical support

- Comprehensive product warranty

- Fast response to inquiries

- Quick delivery

- On-site installation and maintenance service

- Training and technical support

- Customized solutions according to customer requirements

Packing and Shipping:

Packaging and Shipping for Stainless Steel Knitted Wire Mesh:

Stainless steel knitted wire mesh is securely packaged in cardboard boxes with styrofoam inserts to protect the wire mesh during shipping. The boxes can then be sealed with tape and labeled for shipping

The mesh can also be rolled up and placed in a cardboard tube, then secured with tape and labeled for shipping

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!