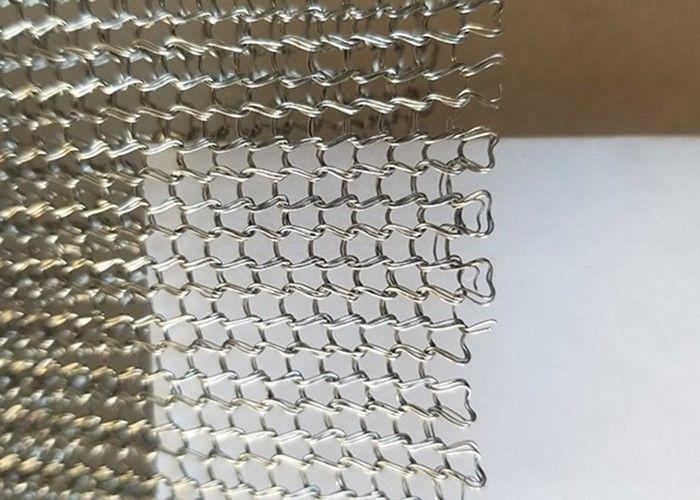

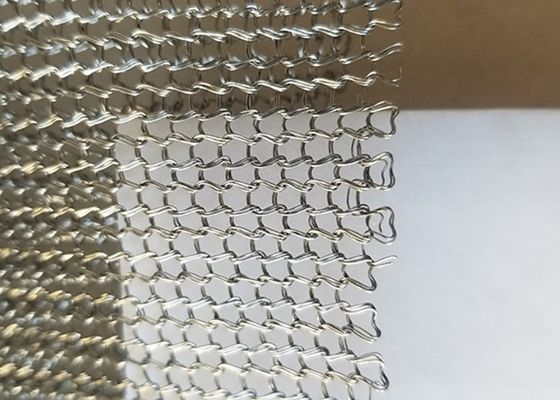

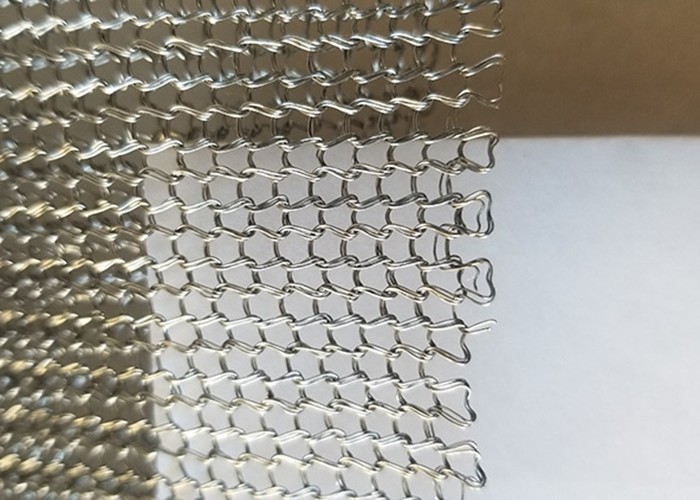

Waved 316L knitted wire mesh corrugations

Knitted wire mesh options in Yuanqiao:

We provide custom manufactured knitted wire mesh specified by the client. Typical stainless steel, polypropylene mesh are maintained in inventory. Other alloy steels and polymeric materials are available by special order. Extremely high surface area units by co-knitting of stainless steel and multifilament glass fiber or PTFE fiber are available by special order. We are able to provide technical input for material selection to the customers.

The relationship between knit mesh wave size and demister characteristics:

Knitted wire mesh demister performance is evaluated on the basis of efficiency, pressure drop, and corrosion resistance. Efficiency is a well-characterized property of a knitted wire mesh mist eliminator. It is primarily a function of droplet size, wire size, surface area of the mesh, pad thickness and physical properties of the system.

Berief introduction of knitted wire mesh:

Gas liquid filter screen is also known as vapor liquid filter screen, foam breaking screen, packing screen, gas liquid screen, foam catching screen, woven screen, knitted screen, braided screen and shielded metal screen. It is a kind of wire mesh woven in special form, which is used to make wire mesh demister and wire mesh mist eliminator in chemical industry, to eliminate or capture the fog drop and liquid foam entrained in the gas in the process of catalyst and distillation, evaporation, absorption, etc.; it is used for oil-gas separation, oil-water separation, gas-liquid separation, shock absorption and silencing, sealing in the manufacturing process of mechanical equipment components, etc.; used for dust removal, water removal, mist removal and air purification in the field of environmental protection, flue gas desulfurization, water treatment equipment, oil-water separator; separation and filtering devices for various occasions; filter elements for automobiles and tractors; sealing, shock absorption (shock avoiding), noise reduction and exhaust purification elements in automobile parts; shielding devices for electromagnetic interference of electronic and electrical products are widely used. The most widely used occasions of gas-liquid filter screen products in China are: oil, petrochemical, chemical, light industry, medicine, metallurgy, aerospace, ship, automobile, machinery, noise damping, pressure vessel, drying tower, absorption tower, desulfurization tower, water mist and dust removal of environmental protection engineering; it is used for gas-liquid separation and gas-liquid moisture separation in the process of filtration, screening, catalyst and distillation, evaporation, absorption, etc.

Deep processing of knitted wire mesh:

No doubt we produce and supply knitted wire mesh demisters, too. Usually a fast delivery within 3 days can be expected if the order is not too big nor too complex.

Knitted wire mesh demister reference:

|

Mesh

Density

|

Eq to: YORK |

Description |

| 80 |

931 |

For a given load of mist, the highest flow velocity is achieved of all styles. Ideal where it is required to minimize the pressure loss, possible clogging is concerned, the size of particle to be collected is relatively large, and/or a very high efficiency is not required. |

| 144 |

431 |

Used for general purposes. An efficiency of 98 to 99% is achieved at a velocity of 1 to 5 m/sec. |

| 192 |

421 |

Used where an especially high efficiency is required. While a pressure loss is slightly higher, it achieves an efficiency of 99 to 100% with particle sizes 3μ or more at a velocity of 1 to 6 m/sec., and is ideal where an efficiency of 90% or more is required at a velocity of 1 m/sec. or less. |

| 216 |

|

Used for collecting fine particles of 1 to 3μ in size.

Especially for a low-density mist of 1.0 g or less, it is used in a thickness of 200 to 300 mm. |

| 432 |

333 |

Used for collecting fine particles. An efficiency higher than that of 216 can be achieved. The most remarkable characteristic is that it provides a high efficiency with a reduced thickness. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!