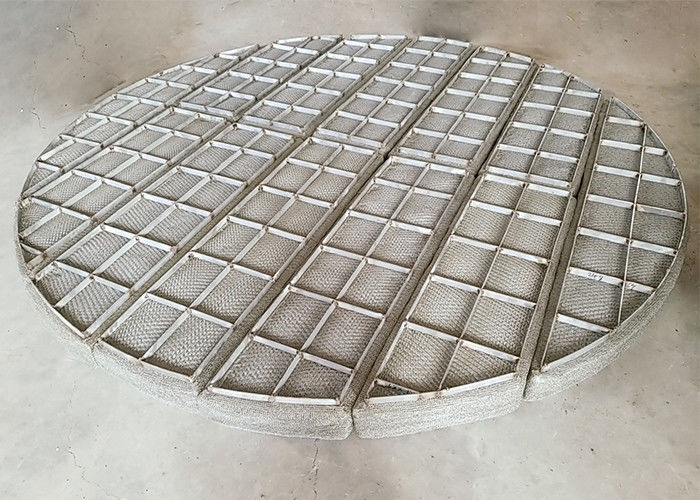

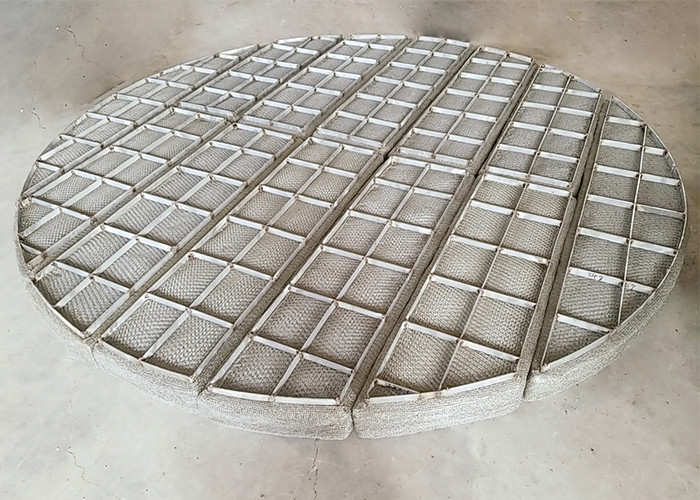

4.5m Diameter Wire Mesh Demister , Efficient Mesh Pad Engineering

The wire mesh demister is installed above the surface of the liquid with some distance. From one hand it allows some space for the natural disengagement of the coarsest natural particles. From the other hand, it ensures that the gas/ vapour flow is uniform over the whole area of the mist eliminator

The gas / vapor containing droplets passes into mesh pad demister at a predetermined velocity. It easily finds open path through the mesh but the droplets and mist impinge on the filaments of mesh where they coalesce and eventually grow to such a size to overcome surface tension of liquid and force of gravity. Then the liquid droplets so formed fall down. And the mist free gas / vapour passes through the mesh demister pad.

Wire Mesh Demister Specifications in this case

| Item |

Value |

Unit |

| Material |

SS321 |

/ |

| Shape & Size |

Φ4500 |

mm |

| Mesh Thickness |

100 |

mm |

| Demsiter Height |

150 |

mm |

| Wire Diameter |

0.23 |

mm |

| Mesh Density |

193 |

kg/m3 |

| Void Fraction |

0.976 |

/ |

| Specific Area |

423 |

m2/m3 |

| Grids |

25*3 flat bar |

mm |

Though the demister is deemed the standard type because it is used in many fields, this model is strong and highly efficient. The demister is used in places where it is necessary to reduce accompanying airborne droplets to a minimum.

The demister safely functions because the design adapts to changes in gas or fluid flow rate. Generally, the 100mm mesh pad is used, but the mesh pad of greater thickness is used where the flow rate changes extensively, offering increased production.

Hualai’s Advantages in mesh pad demister:

Optimized solutions

Standard configurations

Tailored made configurations

Expedited services available

knowledge and engineering experience

High quality manufacturing standards and procedures

Manufactured in a variety of corrosion resistant materials (Metals, Plastics and Co-knit mesh options)

Located in Anping, China, we enjoy many advantages like convenient material purchasing, lower labor cost, faster courier service, etc.

Demister Material we usually use: PP, PTFE, SS304, SS304L, SS316, SS316L, SS201, SS202, SS301S, SS321, Copper, Nickel, Titanium, Duplex 2205, Duplex 2507, NS-80, Monel 400 alloy, Co-knit 904L+fiber glass, Co-knit 316L+ fiber glass, Co-knit 316L+PP flat.bar

Tks for your reading ,hope my introduction can make you clear,any question ,just let me know freely ,i will give you quotation asap.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!