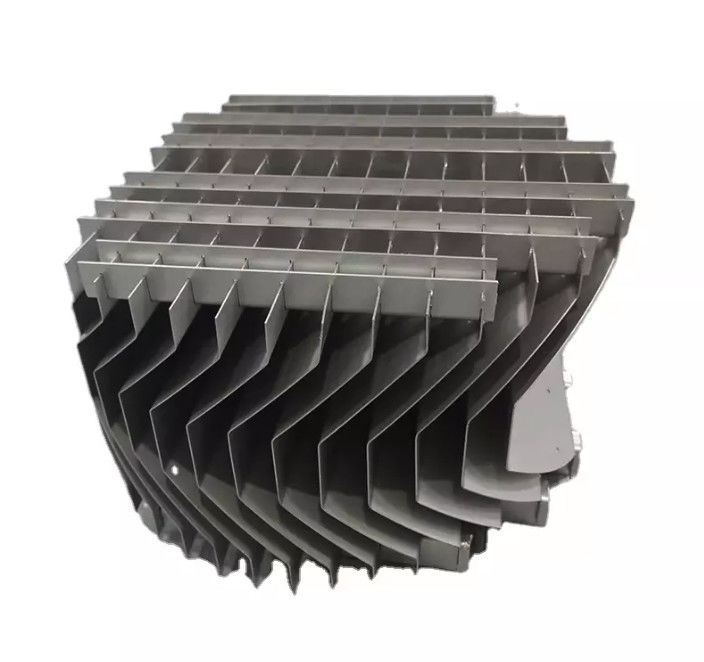

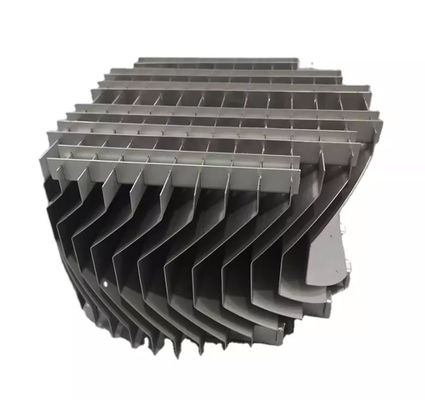

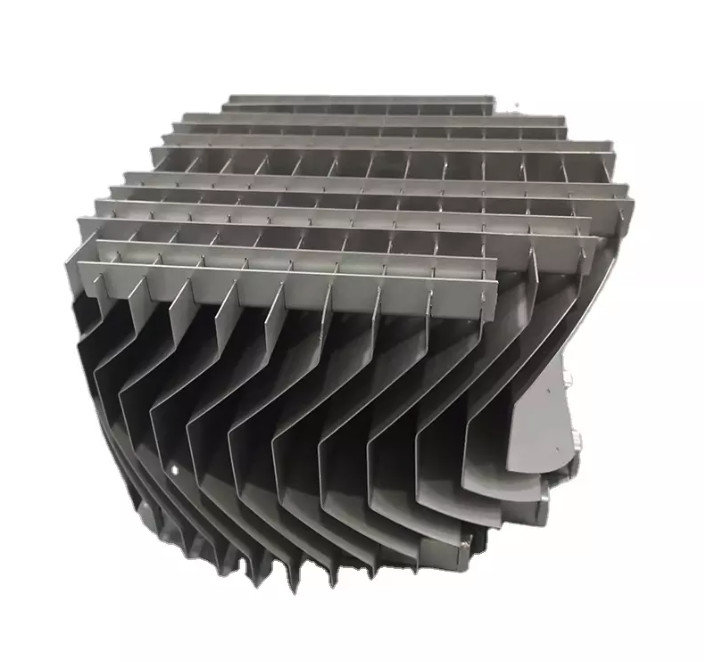

500mm Diameter C Type Vane Pack Mist Eliminator

Vane Pack Mist Eliminator brief introduction

In the process of industrial production and industrial waste gas discharge,gas-liquid separation is an important process.

Our Vane Pack Mist Eliminator isStable performance, long life,Easy to be cleaned Apart the air and liquid, high efficiency

Vane Pack Mist Eliminator Technical Parameter

| Items |

Specific Introduction |

Unit |

| Materials of drift eliminator |

Stainless steel |

|

| Tem Resistance |

200℃ |

℃ |

| Baffle plate thickness |

Set by Customer Requirements |

mm |

| Price |

Lower |

Higher |

Higher |

RMB |

| Form |

Horizontal Type ( Plate Type ), Herringbone Type ( Weir Type ), V Type , Combined Type. etc. |

|

| Area of drift eliminator |

The inner diameter of the desulfurization tower area or cross-sectional area of flue |

m2 |

| Flow velocity of air tower |

Plate Type 3-4m/s,Weir Type 2.5-5.5 m/s |

m/s |

| Degree |

Two degrees |

degree |

| Interval and height between baffle plates |

Designed by different desulphurization craft |

|

| Flushing layers of flushing system |

Upper and bottom of first-degree drift eliminator, bottom of second-degree drift eliminator; Configurable and topper layer of some drift eliminator be flushed in hand |

laye |

Vane Pack Mist Eliminator Application:

Vane pack mist eliminator is widely used in various applications to separate liquid droplets from gas streams, in all applications where a contact between liquid and flowing gas, the vane pack demister can supply a good performance. Additionally, tiny mist droplets can be carried away with the gas.

It is widely used in the foaming system and high liquid viscosity system in refineries, chemicals, petrochemicals, pharmaceuticals, dyes and intermediates, aromatics and other process industries.

Vane Pack Mist Eliminator Advantage

This technical specification is applicable to the bidding of absorber demister, including the technical requirements for the functional design, structure, performance, manufacture, installation, supply, commissioning and test of the body and auxiliary equipment system of two-stage high-efficiency flat demister.

We will make it in strict accordance with the drawings provided by the customer and meet the technical requirements on the drawings. Any modification or change to the drawings must be approved by the customer.

All equipment and components provided by the manufacturer are mature and reliable and advanced in technology. After several years of operation, it has been proved to be a fully mature and reliable product.

Vane pack demister work condition

The parameters of flue gas collected by closed coke storage system of delayed coking unit are shown in Table 1; After dust removal and desulfurization, it is discharged from the top of the flue gas tower, and the parameters of the net flue gas are shown in Table 2.

Table 1 Flue gas design parameters (case)

| No. |

Item |

design parameters |

Note |

| 1 |

Flue gas flow rate |

31000 m3/h |

|

| 2 |

Flue gas temperature |

normal atmospheric temperature |

|

| 3 |

H2O |

7.3 Vol% |

|

| 4 |

O2 |

19.4Vol% |

|

| 5 |

H2S |

50mg/Nm3 |

|

| 6 |

Dust |

20mg/Nm3 |

Oxygen content 3%, standard state, dry basis |

Table 2 Outlet flue gas parameters (case)

| No. |

Item |

Unit |

Design condition |

| 1 |

Flue gas flow rate |

m3/h |

32500 |

| 2 |

Temperature |

℃ |

~40 |

| 3 |

humidity |

wt% |

13.3% |

| 4 |

H2S |

mg/Nm3 |

<25 |

| 5 |

Dust |

mg/Nm3 |

<10 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!