Pass Iso Ss316l 904l Metal Pall Ring 25mm Tower Random Packing

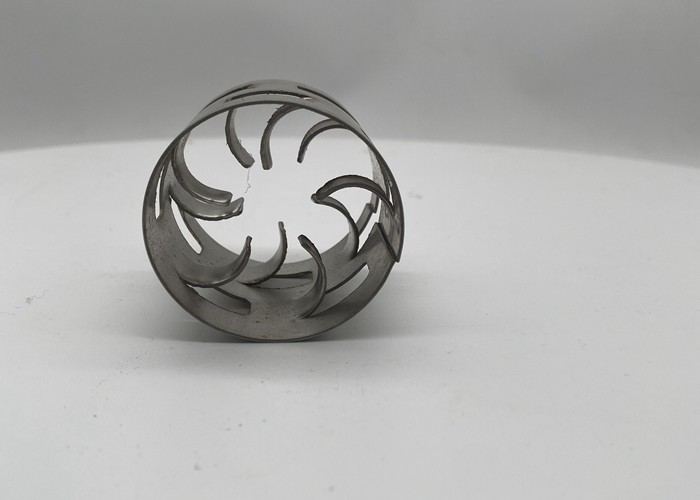

SS316L 25mm Tower Random Packing Stainless Steel Metal Pall Ring

Product Introduction

Metal pall packing is made of carbon steel,stainless steel, aluminum or other materials.

The product has features such as thin wall, heat resistant,high free volume, high capacity, low resistance, high separation efficiency and so on.

It is especially suitable for rectification towers under vacuum to treat thermosensitive, decomposable, polymerizable or cokable systems, so it is widely used in packing towers in petrochemical industry, chemical fertilizer industry and environmental protection, etc.

Application

Metal pall rings can be applied to various of device of isolation, separation, absorption, desorption and pressure reducing.

Advantages

High efficiency

Easily Wettable

Good Liquid and Gas Distribution

Excellent stain resistance

Attentions

The joint clearance of pall ring shall be less than 0.4mm for DN16, DN25 and DN38mm, and less than 0.8mm for DN50 and DN76.

The upper and lower edges of the ring are not allowed to be dislocated. The end cross section of the pall ring shall be perpendicular to the axial center line and 90 degrees to the side.

There shall be no crack on the surface of packing ring and no burr on the edge of packing.

The package material must be strong enough, to endure loading, unloading and carrying for a few times. And it shall protect the pall rings to reach destination safely. Rain proof and moisture-proof measures shall be taken for metal pall rings during transportation. The random tower packing stainless steel pall rings shall be stored in a dry and non corrosive place. Do not store the pall rings in broken packages.

In 1940s, a famous Gemeny company modified the raschig ring greatly. In metal raschig rings, they open several windows on the side wall with inward blades. Without increasing the surface area of the packing, the flow of gas-liquid two-phase in the packing layer is greatly improved, and the hydrodynamics and mass transfer performance of the packing are improved.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!