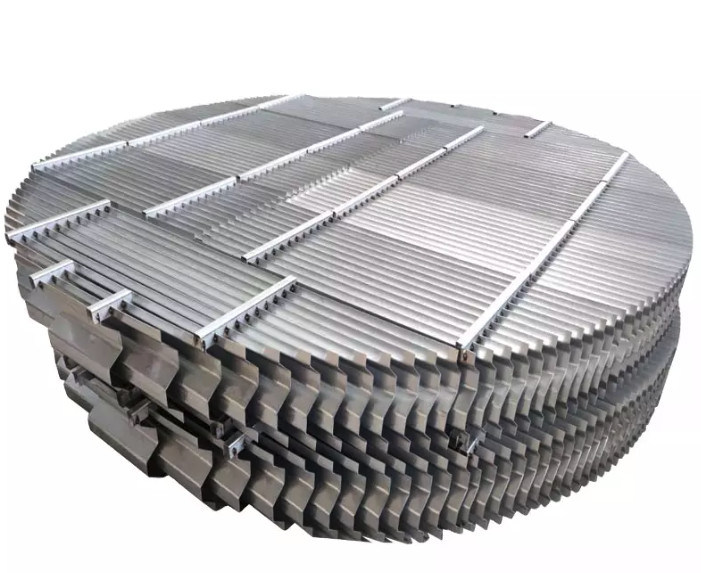

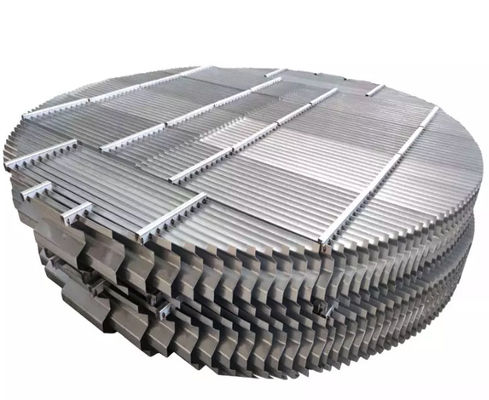

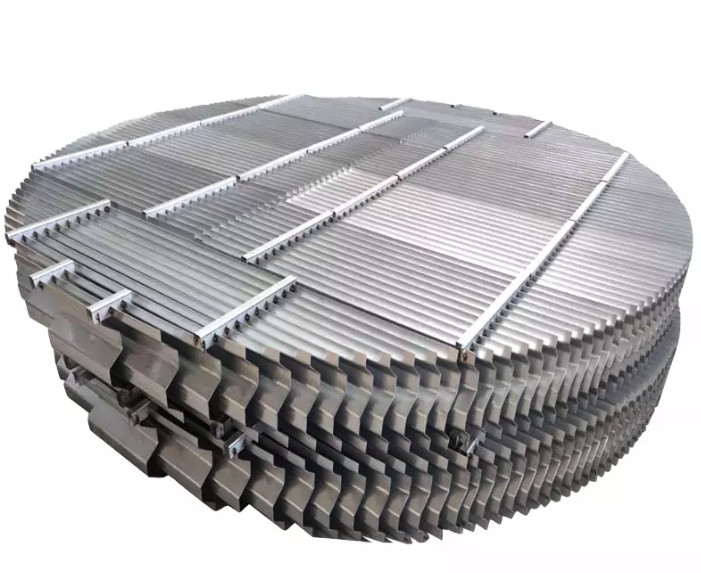

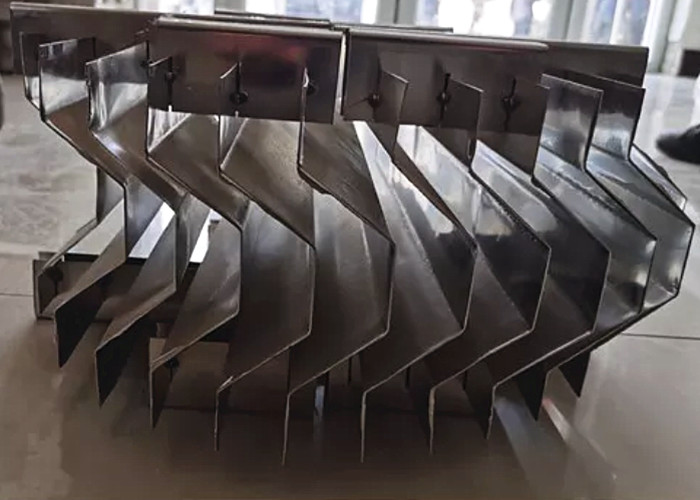

Absorber Tower 170mm Vane Pack Chevron Demister Mesh

Absorber Tower Vane Pack Demister design and manufacturing

1. Absorber demister in Hualai factory,

This technical specification is applicable to absorber demister, including the technical requirements for the functional design, structure, performance, manufacture, installation, supply, commissioning and test of the body and auxiliary equipment system of two-stage high-efficiency flat demister.

We will make it in strict accordance with the drawings provided by the customer and meet the technical requirements on the drawings. Any modification or change to the drawings must be approved by the customer.

2. Technical characteristics of vane pack demister:

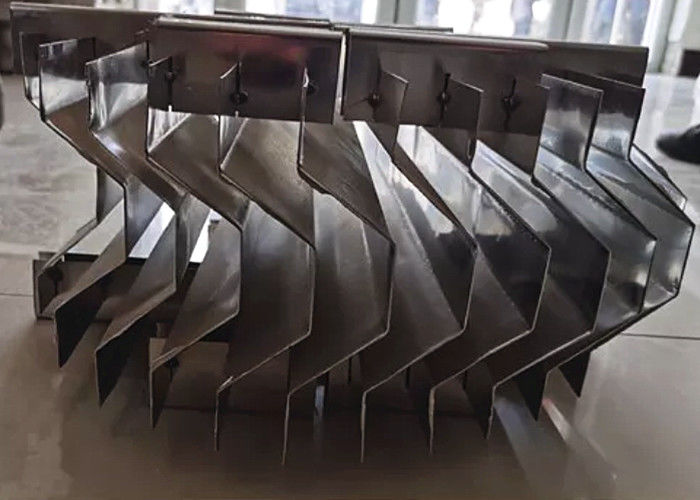

Unique design, without dead angle of demisting in the whole tower, triangle installation form, good stability, unique angle design. Hook on the chevron plate is an option, to gain droplet collection acceleration, and improve separation efficiency.

3. Design technical parameters of vane pack mist eliminator:

| No. |

Item |

Unit |

Data |

| 1 |

Absorber (case) |

|

|

| 1.1 |

Diameter of front passage of demister |

m |

Φ2.6 |

| 1.2 |

Raw flue gas flow of single tower (wet) |

m3/h |

31000 |

| 1.3 |

Net flue gas flow of single tower (wet) |

Nm3/h |

32500 |

| 1.4 |

Net flue gas temperature |

℃ |

45 |

| 1.5 |

Average velocity of flue gas before demister |

m/s |

≤2 |

| 1.6 |

Spray mode of absorption tower |

downward |

downward |

| 1.7 |

Absorber nozzle type |

|

Hollow cone |

| 1.8 |

Average droplet size(D32) |

μm |

2000 |

| 1.9 |

Flue gas temperature: normal operation / design |

℃ |

45/80 |

| 1.10 |

Cl-concentration |

ppm |

<40000 |

| 2 |

Demister data |

|

|

| 2.1 |

First stage vane plate demister |

|

|

| 2.1.1 |

Type |

|

|

| 2.1.2 |

Material |

|

|

| 2.1.3 |

Weight |

kg |

|

| 2.2 |

Second stage vane plate demister |

|

|

| 2.2.1 |

Type |

|

|

| 2.2.2 |

Material |

|

|

| 2.2.3 |

Weight |

kg |

|

| 2.3 |

Liquid holding capacity of flue gas at demister outlet (dry, standard state) |

mg/Nm3 |

|

| 2.4 |

Pressure drop (two stage plate) |

Pa |

<150 |

| 2.5 |

Material of demister |

|

|

| 2.6 |

Spray pipe material |

|

|

| 2.7 |

Total weight of spray pipe |

kg |

|

| 2.8 |

Nozzle material |

|

|

| 2.9 |

Nozzle pressure drop |

bar |

|

| 2.10 |

Number of nozzles |

pc |

|

| 2.11 |

Nozzle unit weight |

kg |

|

| 3 |

Flushing water volume |

Fill in by 100% |

|

| 3.1 |

Upper part of the first stage |

m3/(h·m2) |

|

| 3.2 |

Lower part of the first stage |

m3/(h·m2) |

|

| 3.3 |

Upper part of the second stage |

m3/(h·m2) |

|

| 3.4 |

Lower part of the second stage |

m3/(h·m2) |

|

4. Vane Plate Parameters for Absorber Demister:

1. Height of the first stage vane plate: 170mm,

plate thickness: 3mm; pitch of vane 30mm;

Vane plate shape: streamline 2-channel.

2. Height of the first stage vane plate: 170mm,

plate thickness: 3mm; pitch of vane 25mm;

Vane plate shape: streamline 2-channel; hook in the middle of plate is an option.

3. Molding process: extrusion molding

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!